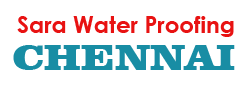

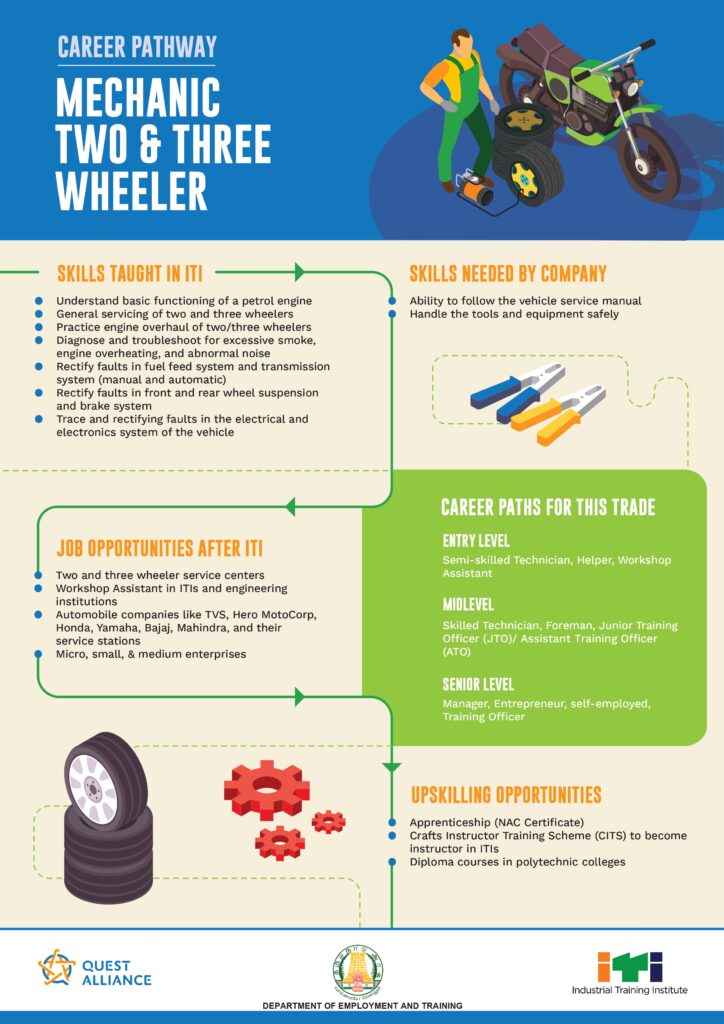

Mechanic Two And Three Wheeler

One Year - Engineering – NSQF Level -3

Professional Skill Attained by the trainee through practical training at ITI’s

- identification of tools & equipment, raw materials used

- dismantling Engine of Two and Three-Wheeler as per given standard procedures

- achieve skill on Overhauling of Cylinder Head, valve train, Piston, connecting rod assembly, crankshaft, flywheel and mounting flanges, spigot and bearings, camshaft etc

- practice reassembling all parts of engine in correct sequence as per workshop manual

- Perform troubleshooting of Excessive smoke, knocking or abnormal noise etc

- Practice servicing of Fuel Tank and its components, repair and overhaul Steering and suspension system of three wheelers

- overhaul brake system, transmission system and LPG/CNG fuel system of Two and three wheelers

- Perform servicing and maintenance.

Specific Learning Outcome from the Trainees

- Comply with environment regulations and housekeeping in the work shop following safety precautions. (ASC/N9801)

- Check &Perform precision measurements and marking by using various measures and marking tools used in automotive work shop practices. (ASC/N1420)

- Plan and Perform basic fastening and fittings operation by using correct hand tools, machine tools and equipments. (ASC/N1420)

- Perform surface finishing operations in the given job. (ASC/N9423)

- Construct electrical circuits and test its parameters by using electrical measuring instruments. (ASC/N1420)

- Perform basic electrical testing in two and three wheelers. (ASC/N1420)

- Perform battery testing and charging operations. (ASC/N1420)

- Construct basic electronic circuits and testing. (ASC/N9424)

- Join Components by using Arc & Gas welding. (ASC/N9425)

- Inspect the Auto component using nondestructive testing method. (ASC/N1420)

- Identify the hydraulic and pneumatic components in a vehicle. (ASC/N1420)

- Check and interpret vehicle specification data and VIN, select & operate various service station equipment. (ASC/N1420)

- Carry out the general servicing of two and three wheelers. (ASC/N1420)

- Carry out Engine overhaul of two/three wheelers. (ASC/N9426)

- Overhauling of cylinder head assembly. (ASC/N9427)

- Diagnosis and trouble shoot for excessive smoke, engine overheating and abnormal noise. (ASC/N1420)

- Carry out Servicing of fuel tank. (ASC/N1420)

- Carry out overhauling of steering and suspension system. (ASC/N1420)

- Overhauling front and rear wheels, brake. (ASC/N1420)

- Overhaul automatic/manual transmission of two and three wheeler. (ASC/N9428)

- Overhaul AC generator. (ASC/N9429)

- Check ignition circuit for proper functioning. (ASC/N1420)

- Overhaul the LPG/ CNG fuel supply system and check exhaust smoke. (ASC/N9430)

- Carry out servicing and maintenance of Electric two and three wheeler. (ASC/N9431)

- Carryout survey of fuel injection system components. (ASC/N9432)

- Read and apply engineering drawing for different application in the field of work.

- Demonstrate basic mathematical concept and principles to perform practical operations. Understand and explain basic science in the field of study.

Machineries and Equipment Handled by the Trainees:

Two Wheeler – Bike Engine / Three Wheeler – Auto Engine, cut section model in 2&3 wheeler engine.

Previous

Next